When it comes to choosing the right type of stainless steel for your project, understanding the difference between Hot Rolled (HR) and Cold Rolled (CR) stainless steel is essential. Both types have their unique properties, applications, and advantages — and at Ujala Stainless, we make sure you get the right material for your industrial needs.

Let’s break it down clearly and technically.

What is Hot Rolled Stainless Steel?

Hot rolled stainless steel is produced by rolling the steel at a high temperature — typically over 1700°F (927°C) — above the steel’s recrystallization point. This process makes it easier to shape and form large pieces of metal.

Key Characteristics of Hot rolled steel

- Rough surface finish

- Less precise dimensions

- More affordable

- Ideal for structural applications

Commonly Uses

Hot rolled stainless steel is widely used in:

- Structural components

- Industrial machinery

- Railway and truck frames

- Pressure vessels

What is Cold Rolled Stainless Steel?

Cold rolled stainless steel starts as hot rolled steel but undergoes additional processing at room temperature. It is further rolled, annealed, and pickled to achieve a smoother surface, tighter tolerances, and enhanced strength.

Key Characteristics

- Smooth polished surface

- Precise dimensions and sharper edges

- Higher strength and hardness

- More expensive than HR steel

Common Uses

Cold rolled stainless steel is preferred in:

- Kitchen equipment

- Appliances

- Architectural applications

- Automotive components

- Furniture and decorative parts

Key differences - Hot rolled vs Cold rolled steel.

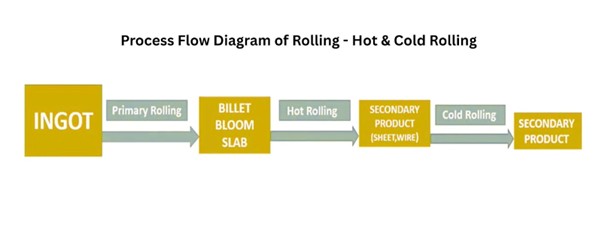

1. Processing Methods

Hot Rolled Stainless Steel

- Processed above the recrystallization temperature (often over 1100 degree C to 1700 degree F).

- ambicasteels.com

- Starts as a large billet or slab that’s heated and passed through rollers, forming plates or coils.

- Produces a rough surface with mill scale and less dimensional precision.

Cold Rolled Stainless Steel

- Made by taking hot-rolled steel and rolling it again at room temperature, or below the recrystallization point.

- Involves extra steps like drawing, grinding, and polishing for a superior finish and tight tolerances.

Surface & Dimensional PrecisionHot Rolled:

Hot Rolled

- Rougher finish with scale, uneven edges, and slight warping during cooling.

- Generally less expensive due to a simpler process.

Cold Rolled:

- Smooth, shiny surface with accurate edges and angles.

- Superior straightness and tight tolerances—ideal for visible or precise applications.

Mechanical Properties & Internal Stress

Hot Rolled:

- Excellent formability, ductility, and toughness.

- Minimal internal stress due to gradual cooling.

Cold Rolled:

- Enhanced strength and hardness (up to ~20% more compared to hot-rolled).

- May carry internal stresses that necessitate stress relief to prevent warping when machined.

Applications & Best Uses

Hot Rolled:

- Cost-effective for heavy-duty, non-critical-surface applications.

- Common in construction beams, structural frames, and general fabrication.

Cold Rolled:

- Ideal for aerospace components, appliances, architectural finishes and automotive parts.

- When aesthetics, dimensional accuracy, and performance matter most, cold rolled is preferred.

Choosing the Right Type

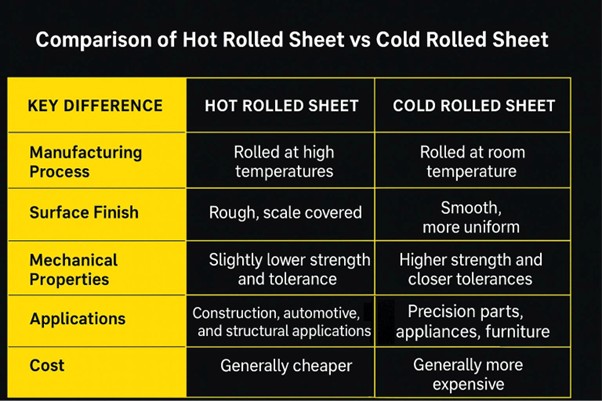

Consideration | Hot-Rolled Stainless Steel | Cold-Rolled Stainless Steel |

Surface Finish | Rough, scale, less appealing | Smooth, polished, visually attractive |

Dimensional Accuracy | Moderate: variations are possible upon cooling | High: tight tolerances ideal for precision work |

Strength & Hardness | Standard | Up to ~20% stronger due to work hardening |

Internal Stress | Low, gradual cooling | Higher, stress relief may be necessary |

Cost | Generally lower due to a simpler process | Higher, due to additional processing steps |

Best For | Structural frames, industrial parts | High-precision, visible, or high-stress applications |

Both hot rolled and cold rolled stainless steel are invaluable, and their suitability depends entirely on your project’s needs:

- Choose hot rolled when cost, toughness, or simple utility is key.

- Opt for cold rolled sheets when visual quality, tight dimensions and strength are essential, even if cost is higher.

At Ujala Stainless, we understand these material subtleties. Whether you’re building heavy-duty infrastructure or sleek, precision components, we can help you select the stainless steel that fits your technical and aesthetic goals.

Add Your Heading Text Here

Conclusion:

Making the Right Choice with Ujala Stainless

When it comes to hot rolled vs. cold rolled stainless steel, the right choice depends on your project needs. Hot rolled stainless steel is ideal for applications that require durability, strength, and cost-effectiveness, while cold rolled stainless steel offers superior finish, tighter tolerances, and precision for high-end uses. Understanding these differences helps you make informed decisions that save time, reduce costs, and ensure long-lasting results.

At Ujala Stainless, we specialize in delivering premium-quality stainless steel products that meet industry standards and exceed expectations. Whether you need hot rolled or cold rolled stainless steel, our expert team ensures you get the right material for your unique requirements.

Ready to source the best stainless steel for your project? Contact Ujala Stainless today for trusted quality and unmatched service.