If you have ever walked through an industrial warehouse, you must have heard of the terms carbon steel, stainless steel, and mild steel. But, unless your profile includes a core technical function in industrial operations, you might not know the exact difference, and they may all sound similar to you in characteristics: strong, reliable, metallic.

However, when it comes to choosing the right steel for your applications, details matter more than just these standard labels. It’s not ideal to simply pick a steel type based on a familiar name. What matters is understanding how each steel behaves under stress, reacts to the environment, responds to heat, and ages over time. Where one may offer superior strength, another excels in corrosion resistance. Some are ideal for construction, others for food-grade applications, and some strike a balance in cost-effectiveness and ease of fabrication.

Without diving into these crucial differences, you risk choosing a material that may look right on paper but fail in its required performance. In our blog, we delve into important differences, so you can make an informed decision.

1. What Exactly Are These Steels?

Carbon Steel

Often referred to as “plain carbon steel,” it contains carbon up to 2% with iron and minimal other elements. Available in low, medium, and high-carbon grades—higher carbon content means increased hardness but reduced ductility.

Mild Steel

A specific type of carbon steel with ≤0.3% carbon, it’s ductile, easy to weld, and ideal for general structural use.

Stainless Steel

An iron alloy that includes at least 10.5% chromium, often with nickel, molybdenum and other elements. Its signature feature is corrosion resistance due to a protective oxide layer.

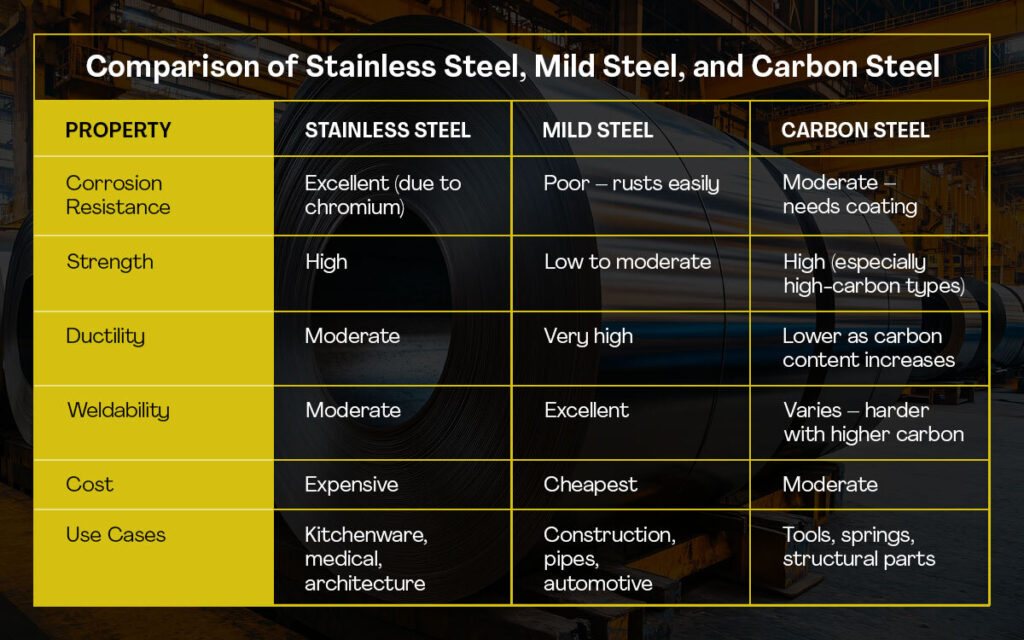

2. Corrosion Resistance & Durability

Carbon & Mild Steel: Prone to rust when exposed to moisture—requires coatings, painting, galvanizing, or powder coating.

Stainless Steel: Naturally resists rust through a self-healing chromium-oxide layer, ideal for humid, chemical, or marine environments.

3. Strength, Hardness & Toughness

Type | Tensile Strength | Hardness & Water Resistance |

Mild Steel | ~370–700 MPa | Softer, more ductile; easy to form and weld |

Carbon Steel | Medium High | Harder, more wear-resistant, but less ductile |

Stainless Steel | High | Harder, maintains shape under load |

- Mild steel is forgiving and adaptable for structural builds.

- High-carbon steel suits tools and situations needing toughness.

- Stainless offers both strength and resilience—great for high-stress, corrosive settings.

4. Cost, Fabrication & Welding

Cost:

- Mild steel is the most cost-effective

- Carbon steel is slightly higher

- Stainless steel is the most expensive due to alloying elements.

Weldability:

- Mild steel: easiest to weld.

- Carbon steel: moderate, but higher carbon requires caution.

- Stainless steel: needs precise techniques to avoid distortion and maintain corrosion resistance.

5. Appearance & Maintenance

- Mild & Carbon Steel: Dull finish; requires regular coatings to prevent rust.

- Stainless Steel: Clean, modern look; low maintenance—buffing and wiping enough to keep it pristine.

6. Typical Applications

- Mild Steel: Structural frames, car bodies, furniture, fencing—everyday applications where durability is key.

- Carbon Steel: Cutting tools, drill bits, machinery parts, springs—where strength outvalues corrosion resistance.

- Stainless Steel: Food equipment, medical tools, marine fixtures, chemical plants—anywhere you need hygiene or corrosion protection.

Which One Should You Choose?

- Budget & Environment: Need durable and low-cost? Go for mild steel, but be ready to paint or galvanize.

- Performance-oriented: Need strong and wear-resistant? Carbon steel is your ally.

- Long-lasting, hygienic, rust-free: You can’t beat stainless steel—worth the higher upfront investment.

At Ujala Stainless Steel, we understand the importance of choosing the right steel based on its usage, functionality, and budget. We believe that making an informed decision about the right steel begins with understanding these factors while balancing cost, performance, and maintenance.

Our experts at Ujala Stainless Steel can guide you based on your needs, application area, and long-term reliability requirements.

Conclusion

Understanding the difference between carbon steel, stainless steel, and mild steel helps you make better decisions for your business.

Carbon steel is strong and ideal for heavy-duty structures.

Stainless steel resists rust and works best in clean or wet environments.

Mild steel is easy to shape and affordable—great for general use.

Each type has its own strengths. Choosing the right one depends on where and how you’ll use it.

At Ujala Stainless, we are a trusted distributor, stockist and supplier of stainless steel products. With over 35 years of experience, we serve businesses across India with quality materials and reliable service.

Need help choosing the right steel? Talk to our team or browse our Steel product range today.

One Response