Buying stainless steel sheets & coils looks simple on paper.

But in reality, many buyers face quality issues, delays, extra costs & performance failures—only because of small procurement mistakes.

At Ujala Stainless, we interact daily with manufacturers, fabricators, EPC contractors & industrial buyers.

Here are the most common mistakes buyers make while sourcing stainless steel sheets & coils—plus how to avoid them.

Mistake 1: Choosing the Wrong Stainless Steel Grade

Not every stainless steel grade suits every application.

Many buyers select grades based on price instead of performance.

This often leads to corrosion, rust spots, cracks, or early replacement.

Example:

- SS 304 for coastal or chemical exposure → wrong choice

- SS 316L for mild indoor use → unnecessary cost

Smart approach:

Always select grade based on:

- Application environment

- Load conditions

- Corrosion exposure

- End-use life expectations

Mistake 2: Ignoring Surface Finish Requirements

Surface finish impacts both appearance & performance.

Buyers often overlook finish details until installation—when it is too late.

Common issues:

- Finger marks visible on panels

- Scratches during fabrication

- Poor aesthetic appeal in elevators or interiors

Always confirm:

- 2B finish

- N4 / No.4 finish

- PVC coated sheets or coils

- Thickness tolerance

Mistake 3: Not Verifying Material Certification

Many buyers skip proper documentation checks to save time.

This can result in:

- Substandard material

- Mixed-grade supply

- Rejected batches during inspection

Always ask for:

- Mill Test Certificate (MTC)

- Heat number traceability

- Grade confirmation from manufacturer

At Ujala Stainless, all material supplied as Jindal Stainless stockist comes with proper certification.

Mistake 4: Buying Only on Lowest Price

Low price often hides high risk.

Cheaper material may mean:

- Improper rolling

- Thickness variation

- Inferior corrosion resistance

Initial savings later turn into:

- Rework costs

- Customer complaints

- Project delays

Better approach:

Focus on value over price—quality, reliability, consistency.

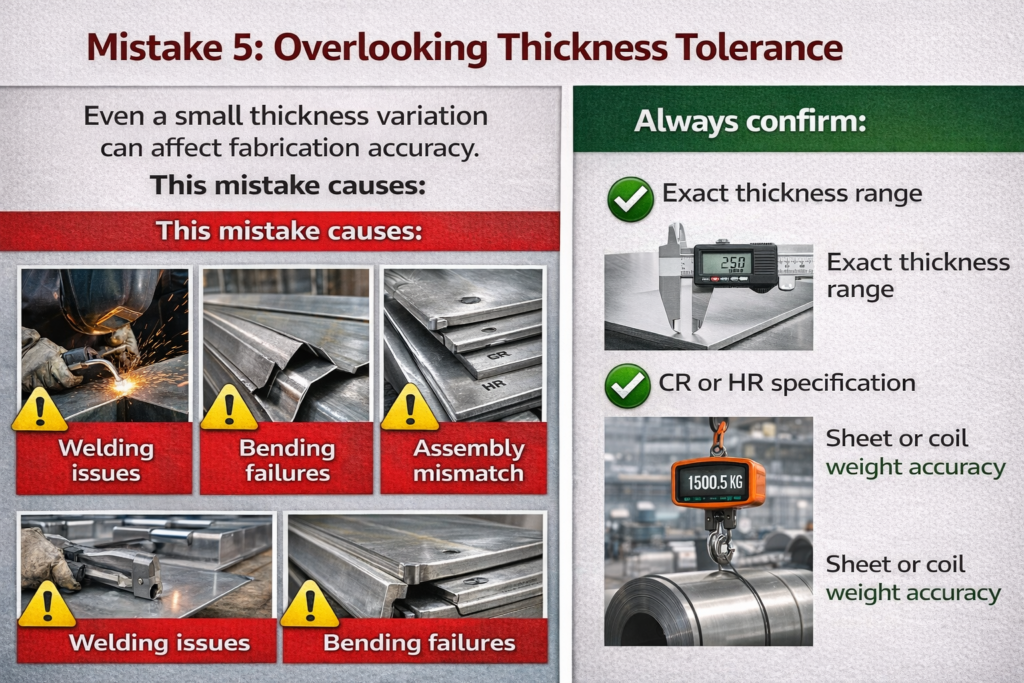

Mistake 5: Overlooking Thickness Tolerance

Even a small thickness variation can affect fabrication accuracy.

This mistake causes:

- Welding issues

- Bending failures

- Assembly mismatch

Always confirm:

- Exact thickness range

- CR or HR specification

- Sheet or coil weight accuracy

Mistake 6: Choosing an Unreliable Supplier

Material quality matters—but supplier reliability matters more.

Unorganized sourcing leads to:

- Delayed deliveries

- Inconsistent supply

- No after-sales support

A trusted stainless steel supplier ensures:

- Ready stock availability

- Timely dispatch

- Technical guidance

- Long-term consistency

Mistake 7: Not Planning Future Requirement Volumes

Many buyers procure only for current demand.

This creates:

- Price fluctuation risk

- Stock shortages

- Urgent sourcing at higher cost

Strategic buyers plan:

- Monthly or quarterly volumes

- Grade-wise consumption

- Project-based allocation

Conclusion: Buy Smart. Buy Reliable.

Stainless steel procurement is not just about buying metal.

It is about choosing durability, safety, consistency & peace of mind.

Avoiding these common mistakes can save cost, time & reputation in the long run.

Ujala Stainless is a trusted supplier & distributor of stainless steel sheets & coils, backed by quality assurance as an authorized stockist of Jindal Stainless.

When quality matters, reliability matters more.

Choose stainless steel that performs—today & tomorrow.