If you are in the manufacturing, construction or engineering industry, you must have heard about cold rolled stainless steel (CRSS).

But what exactly is it and why is it so popular in industries? what makes it different?

Why do engineers, builders and manufacturers prefer it over regular steel? In simple words, cold rolled stainless steel is strong, smooth, corrosion-resistant and perfect for applications that need precision and a polished finish.

In this blog, we’ll break it down in simple terms and explain its common industrial uses.

In this blog, we’ll break down everything about cold rolled stainless steel, including its common industrial uses, advantages and product types. Plus, if you’re looking for a trusted stainless steel supplier, distributor and stockist of Jindal Steel, Ujala Stainless has got you covered.

What is Cold Rolled Stainless Steel ?

Cold rolled stainless steel refers to stainless steel that has been rolled at room temperature, unlike hot rolled steel. The cold rolling process improves strength, surface finish and precision, giving it a smooth, shiny surface and better mechanical properties.

Is 304 Stainless Steel Hot or Cold Rolled?

304 stainless steel can be processed as either hot rolled or cold rolled. Cold rolling is preferred when a smoother surface, higher strength, and precise dimensions are required for industrial applications like kitchen equipment, machinery, or automotive components.

Is 316 Stainless Steel Cold Rolled?

Yes, 316 stainless steel can also be cold rolled. Cold rolling 316 stainless steel enhances its corrosion resistance, strength and finish, making it suitable for marine environments, chemical equipment and high-humidity applications.

Advantages of Cold Rolled Stainless Steel

Cold rolled stainless steel offers several benefits that make it ideal for industrial and commercial use:

- Better surface finish – smooth, shiny and visually appealing

- Higher strength due to strain hardening

- Precise thickness and dimensions

- Excellent corrosion resistance

- Easy to fabricate and weld

- Long service life with low maintenance

These advantages make it a smart choice for industries that demand quality, durability, and hygiene.

Disadvantages of Cold Rolled Steel?

While cold rolled stainless steel has many advantages, it comes with some limitations:

- Higher cost compared to hot rolled steel

- Limited thickness options due to rolling limitations

- Requires polishing or finishing for certain aesthetic applications

- May be less ductile than hot rolled steel for heavy forming

Despite these drawbacks, CRSS is widely used due to its strength, smooth surface and versatility.

What Is Cold Rolled Steel Used For?

Cold rolled stainless steel has a variety of industrial applications: Cold Rolled Steel Examples

Industrial Machinery

Used for precision machinery and equipment that require durable and accurate components.

Automotive Industry

Ideal for body panels, trims and car parts that need both strength and a smooth finish.

Kitchen and Food Equipment

Perfect for sinks, appliances and countertops due to its hygienic surface.

Construction and Architecture

Used for cladding, decorative panels and roofing, offering a polished and long-lasting surface.

Medical and Pharmaceutical

Its corrosion resistance and hygiene-friendly surface make it suitable for hospital and pharma equipment.

Cold Rolled Steel Products

Some common cold rolled stainless steel products include:

- Sheets and coils

- Precision strips

- Industrial machinery parts

- Kitchen appliances and sinks

- Construction panels and cladding

Cold Rolled Steel Examples

Here are a few real-world examples of cold rolled stainless steel applications:

- Automotive panels in cars and buses

- Stainless Steel Kitchen equipment like sinks and countertops

- Decorative architectural panels

- Industrial machine components

- Pharmaceutical & hospital equipment

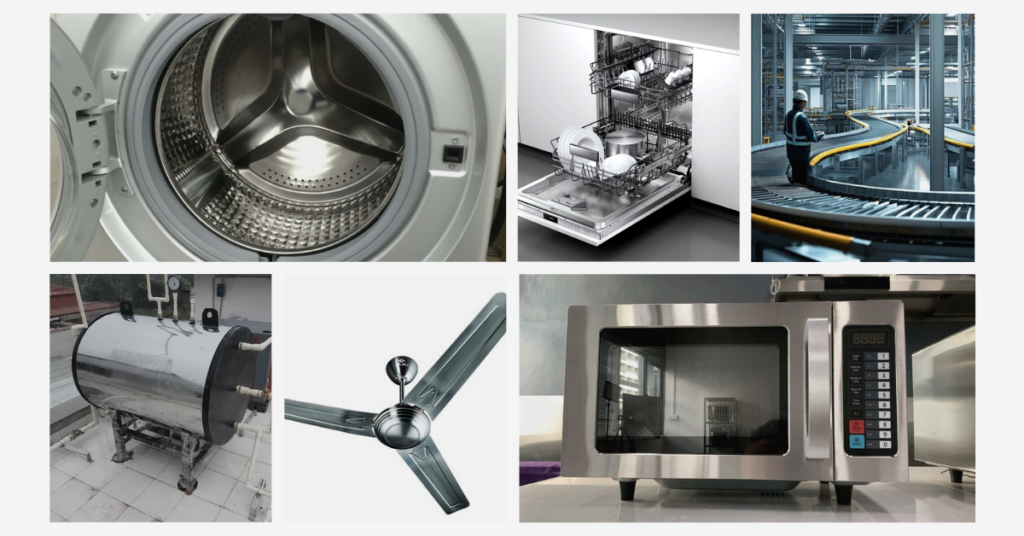

That’s why cold rolled steel is widely used in everyday household appliances such as: Refrigerators, Ovens, fans, water tanks & dishwashers etc.

Because of its strength, smooth finish and long-lasting performance, cold rolled steel is a trusted material that ensures durability and reliability in daily-use appliances.

While cold rolled stainless steel offers superior surface finish and dimensional accuracy, understanding the different between hot rolled vs cold rolled stainless steel differences can help industries choose the right material for their applications.

Why Choose Ujala Stainless for Cold Rolled Stainless Steel?

As a trusted stainless steel supplier, distributor and stockist of Jindal Steel, Ujala Stainless provides:

- Wide range of cold rolled stainless steel sheets and coils

- Timely delivery and consistent stock availability

- Expert guidance for choosing the right grade and finish for your industry

Conclusion: Choose the Right Steel, Choose the Right Partner

Cold rolled stainless steel is the perfect blend of strength, precision, durability and corrosion resistance. Whether it’s for kitchens, construction, machinery or industrial applications, it delivers long-term value.

If you are looking for reliable cold rolled stainless steel from Jindal, partner with Ujala Stainless—your trusted supplier, distributor and stockist.

We supply cold-rolled steel in ASTM A1008, A109, and AISI 1008/1010 grades. It is available in many sizes and quantities, suitable for both small and large orders. Thickness ranges from 0.002″ to 0.134″, with options from drawing quality to full hard. Custom thicknesses and tighter tolerances are available on request.

Contact Ujala Stainless today to get expert guidance, competitive pricing and assured quality for your stainless steel requirements.